Should Techs Bear the Costs to Be ASE Certified?

How useful do you think ASE certification is? We’ve asked the question before, but it’s always good to review. For shop owners who do believe ASE certification is important for their techs, the other related question must be: How much do you invest in getting your techs ASE certified? Certification involves both time and money, and it has assumed benefits for the shop’s reputation in attracting customers. Should techs be responsible for bearing that cost?

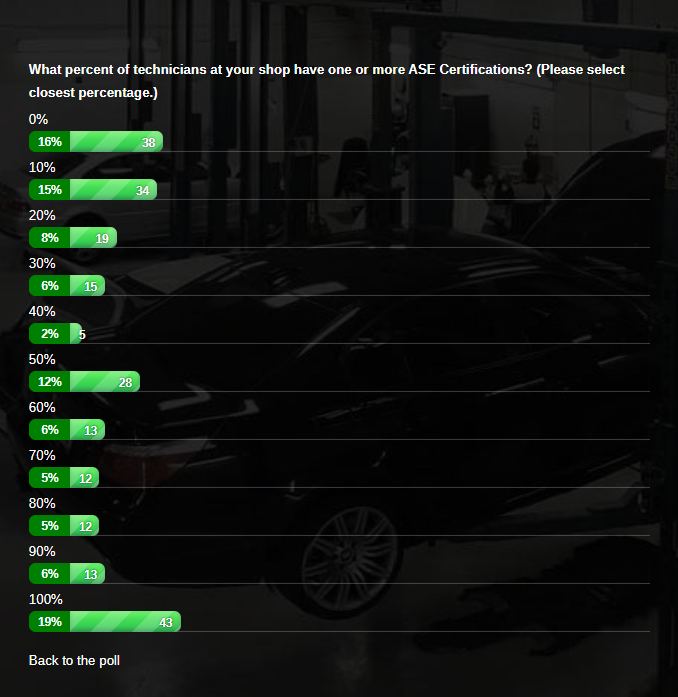

What Percentage of Your Techs Are ASE Certified?

Last year we created a poll that asked: “What percent of technicians at your shop have one or more ASE certifications?” This is what you told us:

According to the results of this poll, 53% of respondents said that at least half of their techs were ASE certified. Only 19%, or less than one in five shops, said all of their techs were ASE certified. This would imply that there is not an industry-wide commitment to this certification.

For many, if not most techs, certification is another hoop to jump through that does not guarantee that they will make more money. Shops will often advertise their ASE certification as a proof of their good quality work. However, to save money, some will give work to techs who are uncertified because they can pay them less. Those shops can make more money while their customers remain unaware of the fact that their cars are not being repaired by certified techs. The kicker is that in this scenario certified techs actually lose work. This does not give them an incentive to become ASE certified.

ASE certification costs techs in two different ways. First, they have to take time off to go to class, learn the material, and be tested. This is time that they could be working for real wages. Secondly, certification costs them money. They might be able to make more money after they’ve gotten their certification, but this is not guaranteed. It depends on the shop, and techs are aware that what is required at one shop is not the case at another.

Auto repair shops can reimburse techs for either or both of these costs. They can choose to pay techs for the time it takes them to go through the certification process, and they can also choose to pay the cost of certification too. Some shops will pay techs for costs when they pass the certification tests. Other make ASE certification a condition of employment and expect that techs will earn that certification on their own.

Another problem is that even if a shop pays for the costs of certification, many repair technicians do not believe that this type of learning makes them better techs. They say the test proves how well they can learn certain facts and repeat them correctly on a test – not how well they can repair cars or how much their practical knowledge base has improved. Because they don’t think it’s a worthwhile use of their time, this is a different kind of personal cost.

Currently there is a shortage of auto techs. This fact has to be considered when determining whether it’s feasible for auto shop owners or managers to demand additional certification. When auto repair shops are already finding it very challenging to employ and keep auto techs, requiring further certification requirements is going to be a hard sell. If a tech knows he can get a job at a shop that doesn’t require additional certification, he’ll go there instead.

What is your shop’s history with ASE certification? Do you pay for your techs to go to class? Do you pay their wages while they attend? Do you pay your certified techs better if they are ASE certified? We would like to know how you handle ASE certification and whether you think it’s valuable, so please weigh in either here or in our forums.

My response is very short on this topic. I paid for my education. Why do technicians continue to feel they are special.

Wow!

First off, it’s great the topic of ASE certification is being talked about. It’s a subject that should be continued.

Personally, I am all for ASE Certification. It’s the only guidepost we have to separate a mechanic from a technician. There are a lot of mechanics out there. Just check out YouTube where you can learn how to pass an emissions test with just a banana. (My attempt at humor)

Apprenticeship programs teach you ABOUT systems, not how to diagnose and repair them and, in any case, if you own a tool box, you can call yourself a mechanic.

So, how does a tech, who has his/her Red Seal ticket, compare themselves to the rest of the industry of mediocrity?

Well, when I first achieved Master Technician status with ASE, I really felt proud of myself for the first time because that was for me. Not for a business or anyone else, but for me and it gave me the drive to continue honing my skills.

What I liked about the exams were the questions; real world symptoms with possible solutions. Which meant you should be well familiar with the workings of each system and know how to fix them.

I do believe we need ASE.

For the apprentice, it gives another goal to reach and the knowledge that Red Seal is just the starting point of becoming a professional technician, not the end of your learning.

For the mechanic, don’t complain or make excuses. Take the tests and find out for yourself if you’re as good as you think you are.

For the business owner; be proud of your ASE techs, especially the Masters, but don’t forget to reflect your appreciation with something extra in their paychecks and yes, tell all your customers you strive to have the best this industry can offer.

Here, in BC, we have the apprenticeship program. But, guess what? Being certified is NOT Provincially mandatory to be a mechanic. That alone has created so much confusion, a deterioration in our education system and, as a result, a serious shortage in qualified trades people for this industry.

Just making it easier for people to call themselves mechanics has proven to be the wrong direction.

Plus if we, within our own industry, don’t set our standards high enough, then how can our customers trust us and our abilities?

Then again, that’s just my opinion.